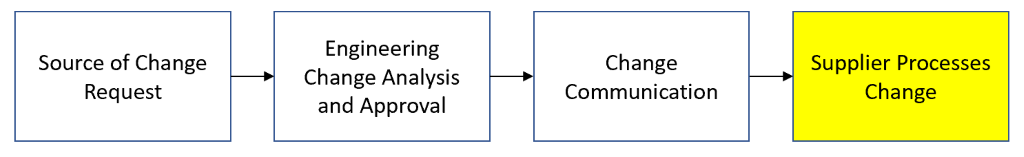

Supplier Processes Change

Once the Engineering Change has been requested, approved, and communicated, the supplier must then make changes to its production plan and inventory levels to address the solution. If models or drawings are provided with the Change Request the supplier must then undergo its translation process to implement the change and then update any other related files, such as NC programs and quality plans. Without revised models, the Supplier often attempts to utilize the information to adjust their working models. This enables them to continue production quickly but increases the risk of non-conforming parts being produced due to miscommunications of the requirements.

The Customer also must decide whether a First Article Inspection (FAI) is required for the revised model or whether it is not necessary. If a FAI is necessary, the customer must communicate this to its related suppliers to initiate the FAI process. In a digital environment, this is often performed by the company’s Portal or their Enterprise Resource Planning software. The FAI requirements are generally documented in the PO or as an attachment to the PO. To fulfill the FAI requirements the supplier must contact the Customer to schedule the FAI procedure so that a Customer representative can be onsite to witness the inspection.

After a change has been made, the Supplier also must address the impact to current inventories. The change notice typically recommends a disposition for current parts. It can recommend using the parts as is, rework the inventory, or that the products should be scrapped all together. Implementing these decisions utilizing digital methods involves using software such as Inventory Management System software or Warehouse Management System software. Utilizing these tools, the supplier can quickly assess the current state of their inventory and coordinate the dispositions of the effected parts quickly. A change may also require finding new materials and component that are not in current inventory. This process is critical to address quickly to meet production schedules.

Supplier Processes Change