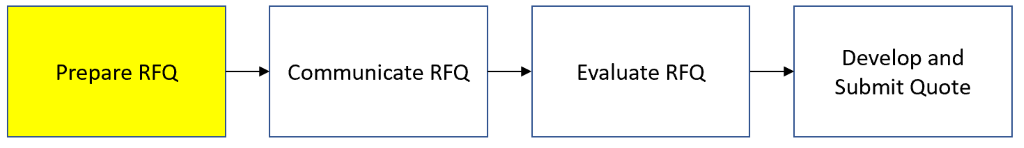

Prepare RFQ

To source a part, the Customer must first prepare a Request for Quote (RFQ) package to be distributed to prospective Suppliers using the Technical Data Package (TDP) for the part. The purpose of the “Prepare RFQ” process is to provide the Product and Manufacturing Information (PMI) necessary for the Suppliers to provide a realistic quote to produce the components and/or provide the process specified by the RFQ. The basic activities may include:

- Preparing 3D models to be used by Suppliers

- Preparing 2D drawing to be used by Suppliers (PDF)

- Providing First Article Inspection (FAI) requirements to be followed by Suppliers

- Providing contractual requirements to be adhered to by Suppliers

- Preparing and providing process and material specifications for use by Supplier.

A digital RFQ is developed from an electronic TDP that contains all the required information needed for a quote in an interoperable digital file format that can easily be used by the Supplier. The use of validation software and review by subject matter experts in the development of the RFQ creates a data structure that can identify missing or inaccurate information and ensure that the RFQ and all technical requirements can be easily understood by the Supplier.

The digital RFQ is created utilizing the product data pulled from the TDP of the part or assembly. The Customer typically fills out much of the information automatically from various structured preset templates and databases. Any CAD drawings or models in the RFQ package are then translated into an interoperable neutral format (STEP, IGES, etc.) and released to potential Suppliers.

An alternative to compiling a digital RFQ by pulling data from the part or assembly TDP is to utilize a Supplier portal that integrates communication and data interfaces. Such a portal allows Suppliers to view, print, and download drawings, models, and specifications the Supplier has permission to access for a given RFQ from the data stored in the Customer’s Product Lifecycle Management (PLM) system. This management of access allows the prospective Supplier to receive only the specific PMI needed for the quote and eliminates the need for the Customer to extract a separate Digital RFQ from the part or assembly TDP. Security with this method, which is a major concern, is managed by the Customer. Only verified Suppliers should be allowed to directly access the technical data for a given RFQ maintained in the PLM system.

prepare rfq