The Customer Supplier Interoperability (CSI) program was sponsored by the Department of Defense and the US Air Force Research Laboratory, ManTech division. The program’s goal was to develop solutions for engineering inefficiencies associated with technical data exchange and to accelerate the adoption of Model-Based Definition (MBD) methodologies in defense supply chains. Through the automation of manual tasks, CAD validation, and advanced toolsets, the CSI program paves the path toward MBD for the defense industrial base.

BENEFITS

- Savings of approximately $50 million per year when fully adopted by all supply chain members in a large defense acquisition program.

- With major programs exceeding 20 years in duration, this could result in more than $1 billion in projected savings.

Source: International TechneGroup

Force Protection Inc. (FPI) develops defense products and vehicles for the government. Their status as a government contractor means that FPI must conform to the strict government rules surrounding the communication of sensitive data. Failure to do so would result in fines or the loss of contracts. In response to this new need for security and accountability, FPI deployed MBE CAD data exchange software throughout its engineering teams, and the software is now used for all design and engineering data transfer.

BENEFITS

- Control, flexibility, security, ease of use

- Now have monthly logs of all data transfer activities, a key requirement for the US government.

- FPI meets all of the strict requirements for security and accountability set by the US government.

Source: International TechneGroup

Thales implemented MBE CAD data exchange software to automate the flow of product data among its internal users. The web-based system provides a convenient, reliable and secure method for translating engineering data. This will be expanded in the second stage of implementation to include data transmission between Thales and its customers and suppliers.

BENEFITS

Source: International TechneGroup

Samsung began by implementing the MBE CAD data exchange software at its Visual Display and Printer Divisions. The MBE CAD data exchange software allowed Samsung to more easily share quality data between various systems including design, collaboration, and data management. Multiple in-house applications utilize MBE CAD data exchange software as a secure backend server, for translations and validation. Samsung’s new data exchange software is also linked to its global suppliers.

BENEFITS

- Delivery of data to customers and suppliers has been reduced from days to minutes

- Improved process efficiency

- Significant time savings

Source: International TechneGroup

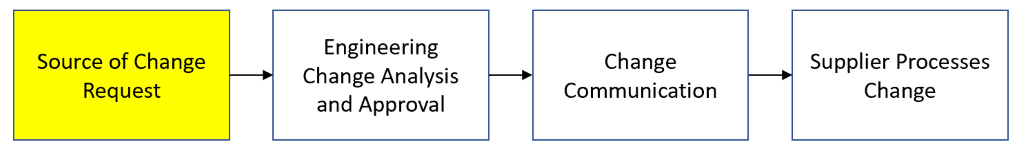

Volvo Car Corporation wished to enable better communication with its suppliers and to transfer the design responsibility of parts and subsystems to those suppliers. Utilizing an electronic product data management system (ePDM), they were able to implement these changes and create a digitalized engineering change environment that was real-time with defined expectations of the priority and speed at which the ECOs were performed.

BENEFITS

- Improved visibility into the ECO process

- Reduced time to implement Engineering change

- Defined ECO expectations

Source: Pikosz & Malmqvist

U.S. Navy Naval Air Systems Command (NAVAIR) Naval Air Warfare Center Aircraft Division (NAWCAD) Model-Based Definition (MBD) Case Study: NAWCAD Lakehurst is the center of excellence for Aircraft Launch and Recovery Equipment (ALRE) and naval aviation Support Equipment (SE). NAWCAD moved to a 3D MBD environment, which required the conversion of conventional 2D drawings to a 3D digital product definition. 3D PDFs containing digital product definition became the single source of data through the product development process.

BENEFITS

- Realize greater than $3 million in annual savings

- Reduced costs, increased quality, shorter schedule cycles

- 33% reduction in new item development schedules expected

Source: International TechneGroup