Force Protection Inc. (FPI) develops defense products and vehicles for the government. Their status as a government contractor means that FPI must conform to the strict government rules surrounding the communication of sensitive data. Failure to do so would result in fines or the loss of contracts. In response to this new need for security and accountability, FPI deployed MBE CAD data exchange software throughout its engineering teams, and the software is now used for all design and engineering data transfer.

BENEFITS

- Control, flexibility, security, ease of use

- Now have monthly logs of all data transfer activities, a key requirement for the US government.

- FPI meets all of the strict requirements for security and accountability set by the US government.

Source: International TechneGroup

Thales implemented MBE CAD data exchange software to automate the flow of product data among its internal users. The web-based system provides a convenient, reliable and secure method for translating engineering data. This will be expanded in the second stage of implementation to include data transmission between Thales and its customers and suppliers.

BENEFITS

Source: International TechneGroup

Samsung began by implementing the MBE CAD data exchange software at its Visual Display and Printer Divisions. The MBE CAD data exchange software allowed Samsung to more easily share quality data between various systems including design, collaboration, and data management. Multiple in-house applications utilize MBE CAD data exchange software as a secure backend server, for translations and validation. Samsung’s new data exchange software is also linked to its global suppliers.

BENEFITS

- Delivery of data to customers and suppliers has been reduced from days to minutes

- Improved process efficiency

- Significant time savings

Source: International TechneGroup

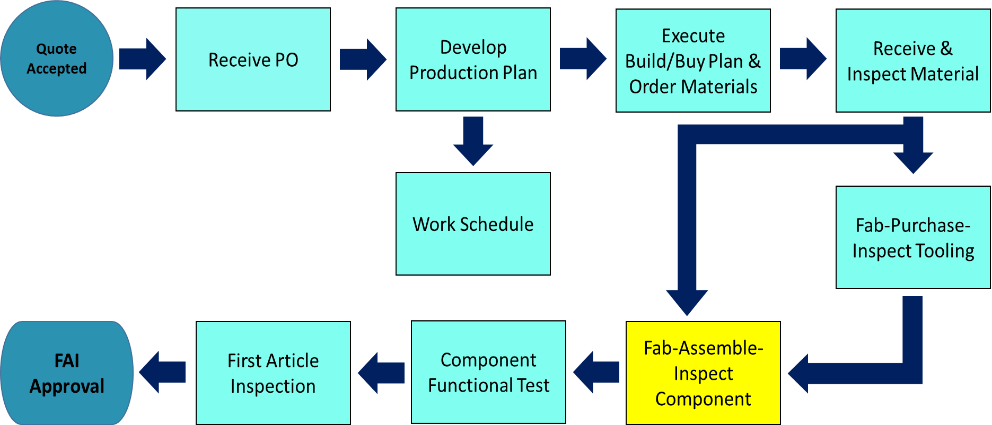

Touch International is a supplier of high-quality touch screens and touch screen components for a variety of applications in medical, industrial, military, aerospace, retail, and gaming industries. Touch International implemented inspection planning and reporting software for all of their first articles. The software is able to balloon and extract drawings in one step, and export directly into an AS9102 report template.

BENEFITS

- 5 hours reduced to 30-45 minutes to generate a moderately complex fully compliant AS9102 first article inspection plan

- 85% time savings and increased efficiency

- In 2017 Touch International completed over 300 inspection plans. This equates to over 1,275 hours of work that was saved.

- 4 inspectors to 1 individual creating inspection reports

UTC Aerospace sought to reduce First Article Inspection (FAI) template creation time. The solution included using First Article Inspection software. Utilizing their previous methods, they were able to make one template in 8 hours on average. Through implementing this change and monitoring the number of Inspections made UTC was able to clearly see how the software was able to reduce cycle time for template creation.

BENEFITS

- 75% Reduction in FAI Template creation time