First Article Inspection (FAI)

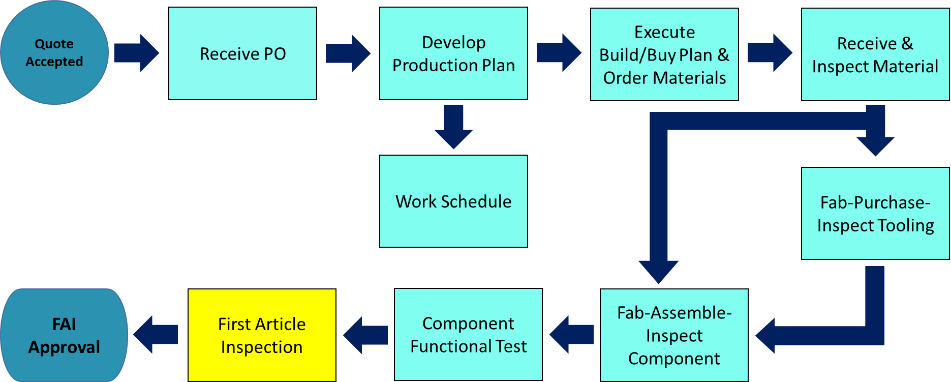

To prepare for the FAI all relevant data regarding the production and inspection of the first article must be gathered into a data package. This includes items such as in-process inspection records and functional test approvals. Also, any material or process certifications from outside suppliers must be gathered and added to the FAI data package. This package along with the first article itself is then sent for the FAI.

Since the FAI is a formal process that involves both the supplier and the Customer it must have representatives from both parties to validate the results. To this end the FAI must be formally scheduled either through informal methods such as email or formally through forms exchanged through a supplier portal.

At the scheduled time both the supplier and the Customer conduct Inspections in accordance with a pre-defined FAI plan. Various tools and applications are used to conduct the FAI depending on the component inspected. Results are documented and the component is accepted or rejected. If rejected a corrective action is developed and implemented and the FAI process is repeated. If accepted, the approval is given for full-rate production.

After the successful completion of the FAI the component must be shipped. To ensure it is not damaged during transit proper shipping containers or crates must be constructed. Additionally, the component may need specialized wrapping and packing materials. This must be designed upfront then executed at this point in order to prepare the component for shipping. Finally, all needed documentations, i.e. shipping lists, certifications, etc., must be included in the shipping container. In parallel to the crating activity, shipping arrangements must be made with appropriate delivery services.

Upon successful delivery and acceptance of the first article the Customer can give the approval for full rate production. This decision must also consider any changes from the customer, material availability, as well as the overall production schedule. Once the decision is made, it is then communicated to the supplier.

First Article Inspection (FAI)